n kev ncua ntawm cov tsheb thauj khoom, tsheb npav thiab lwm yam khoom siv, muaj cov ntsiab lus uas them rau lub sijhawm reactive - dav hlau rods.Kev sib txuas ntawm cov pas nrig nrog cov kab teeb ntawm cov txuas hniav thiab cov thav duab yog nqa tawm nrog kev pab ntawm cov ntiv tes - nyeem txog cov khoom no, lawv hom thiab tsim, nrog rau kev hloov cov ntiv tes hauv kab lus.

Dab tsi yog tus ntiv tes tiv thaiv ntiv tes

Tus pin ntawm lub dav hlau pas nrig yog ib feem ntawm kev ncua ntawm cov tsheb thauj khoom, tsheb npav, semi-trailers thiab lwm yam khoom siv;ib feem nyob rau hauv daim ntawv ntawm ib tug ntiv tes los yog ntiv tes nrog ib tug roj hmab-hlau pob khawm, uas yog lub axis ntawm lub pob khawm kev twb kev txuas ntawm tus pas nrig nrog tus ncej thiab beam ntawm tus choj.

Hauv cov tsheb thauj khoom, tsheb thauj mus los thiab cov tsheb thauj mus los, ib qho kev ncua ntawm lub caij nplooj ntoos hlav thiab caij nplooj ntoos hlav sib npaug yog siv, uas, nrog rau tus qauv tsim thiab kev ntseeg siab, muaj qee qhov tsis zoo.Ib qho ntawm cov teeb meem no yog qhov yuav tsum tau them rov qab rau cov reactive thiab braking torques uas tshwm sim thaum lub tsheb tsiv.Lub sijhawm reactive tshwm sim thaum lub log ntawm lub tsav qag tig, lub sijhawm no zoo li tig lub qag nyob rau hauv qhov kev taw qhia, uas ua rau deformation ntawm cov springs thiab cov tsos ntawm unbalanced rog nyob rau hauv ntau yam ncua kev kawm ntawv units.Lub braking torque ua zoo sib xws, tab sis muaj qhov sib txawv.Txhawm rau them nyiaj rau lub zog reactive thiab braking torque, ntxiv rau kom ntseeg tau tias kev sib txuas ntawm cov axles lossis lub trolley nrog lub thav duab tsis poob lub peev xwm txav mus rau qhov ncua sij hawm nyob rau hauv lub dav hlau ntsug, cov ntsiab lus ntxiv yog nkag rau hauv kev ncua - dav hlau rods.

Dav hlau rods yog mounted rau lub qag kab teeb thiab brackets ntawm lub thav duab nrog kev pab los ntawm hinges uas muab lub peev xwm los tig cov rods txheeb ze rau lub beams thiab lub thav duab thaum hloov txoj hauj lwm ntawm lub ncua kev kawm ntawv qhov chaw nyob rau hauv lub sij hawm ntawm overcoming txoj kev irregularities, thaum. khaws ceev thiab nres.Lub hauv paus ntawm cov pob khawm yog qhov tshwj xeeb - cov ntiv tes ntawm cov dav hlau rods.

Tus ntiv tes ntawm cov tshuaj tiv thaiv pas nrig ua haujlwm ntau yam:

● Kev sib txuas ntawm tus pas nrig nrog cov khoom raug tshem tawm thiab cov ncej ntawm lub tsheb;

● Nws ua raws li lub axis ntawm lub swivel sib koom ua ke, txheeb ze uas tus pas nrig tig;

● Nyob rau hauv cov pas nrig nrog cov roj hmab-hlau hinges - damping shocks thiab vibrations, tiv thaiv lawv hloov ntawm lub ncua kev kawm ntawv mus rau lub thav duab thiab nyob rau hauv lub opposite direction.

Tus pin ntawm cov tshuaj tiv thaiv pas nrig yog ib qho tseem ceeb ntawm kev ncua, yog li yog tias nws hnav, deforms lossis tawg, nws yuav tsum tau hloov.Tab sis rau kev txhim kho kev ntseeg siab, koj yuav tsum paub tias cov ntiv tes yog dab tsi, lawv tau npaj li cas, lawv txawv ntawm ib leeg, thiab yuav xaiv lawv li cas kom raug.

Hom, tsim thiab nta ntawm tus pin ntawm cov tshuaj tiv thaiv pas nrig

Ua ntej ntawm tag nrho cov, cov ntiv tes ntawm lub dav hlau rods muab faib ua ob pawg loj raws li txoj kev ntawm installation thiab fastening:

● Pob ib leeg-txhawb tus pins;

● Ob tug ntiv tes txhawb nqa.

Qhov chaw ntawm thawj hom yog tus qauv ntiv tes ua nyob rau hauv daim ntawv ntawm ib tug conical pas nrig nrog ib lub pob ntawm ib kawg thiab ib tug xov ntawm lwm yam.Lub spherical ib feem ntawm xws li ib tug pin yog mounted nyob rau hauv tus pas nrig, thiab tus pas nrig nkag mus rau hauv lub qhov nyob rau hauv lub bracket ntawm tus ncej los yog beam ntawm tus choj.Lub installation ntawm tus ntiv tes nyob rau hauv tus pas nrig yog nqa tawm ntawm ob lub nplhaib steel liner (breadcrumbs) nrog hemispherical sab hauv qhov chaw uas lub pob ntiv tes tig dawb do.Lub pas nrig ib feem ntawm tus pin tawm ntawm tus pas nrig los ntawm cov roj foob, tus ntiv tes yog tsau siv lub hau bolted, lub oiler yog ntsia rau hauv tib lub hau kom sau lub pob khawm nrog roj.Hauv qee cov pas nrig, lub caij nplooj ntoos hlav txhawb nqa conical nyob nruab nrab ntawm tus pin thiab lub hau, uas ua kom qhov tseeb ntawm qhov chaw.

Pob ib leeg-cov kabmob pins tau muab faib ua ob hom:

● Txheem steel ("liab qab");

● Nrog kev sib xyaw roj hmab-hlau pob khawm (RMS).

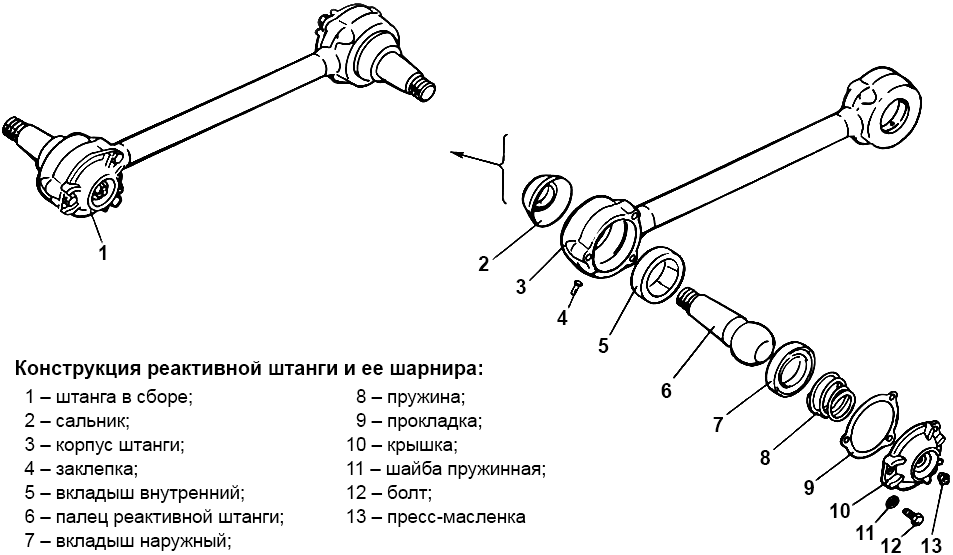

Tus tsim ntawm cov tshuaj tiv thaiv pas nrig thiab nws pob khawm

Tus qauv tsim ntawm tus ntiv tes ntawm thawj hom tau piav qhia saum toj no, cov ntiv tes ntawm hom thib ob tau teeb tsa zoo ib yam, txawm li cas los xij, lub pob khawm roj hmab-hlau yog nyob rau hauv lawv los ntawm ib sab ntawm lub installation nyob rau hauv tus pas nrig, uas muab damping ntawm shocks thiab kev vibration.RMS yog tsim nyob rau hauv daim ntawv ntawm ib lub nplhaib ua los ntawm cov roj hmab tuab los yog polyurethane, uas encircles sab hauv ntawm tus ntiv tes nrog ib tug extension.Tsis tas li ntawd, RMS tuaj yeem kho nrog lub nplhaib hlau.

Nws yog qhov nthuav kom nco ntsoov tias niaj hnub no cov ntiv tes ntawm lub dav hlau rods "nrog ob lub peev txheej" tau muab - ntawm lub plawv ntawm cov khoom no yog ib lub pob zoo tib yam, nyob rau ntawm lub kheej kheej ntawm cov pob khawm roj hmab-hlau.Tom qab cov roj hmab (lossis polyurethane) lub nplhaib hnav, cov ntiv tes raug tshem tawm, cov seem ntawm RMS raug tshem tawm ntawm nws, thiab hauv daim ntawv no yog rov nruab rau hauv tus pas nrig los ntawm cov liners.Ib tug ntiv tes ntawm hom no zoo li ntxim nyiam mus yuav, tab sis qhov zoo ntawm cov khoom zoo li no tsis yog ib txwm siab, thiab rau lawv cov kev hloov raws sij hawm nws yog ib qho tsim nyog yuav tsum tsis tu ncua tshuaj xyuas qhov ncua sij hawm thiab tsis nco lub sij hawm thaum RMS hnav tawm, thiab lub spherical ib feem. ntawm tus ntiv tes tseem tsis tau muaj kev sib cuag nrog lub barbell.Tsis tas li ntawd, ib txheej ntawm cov khoom ntxiv yog yuav tsum tau rov nruab tus ntiv tes, uas ua rau kom cov nqi kho.

Tsis tas li ntawd, pob ib leeg-txhawb tus pins tau muab faib ua ob hom raws li txoj kev kho cov txiv ntoo los ntawm sab ntawm tus choj nqaj hlau bracket lossis ncej:

● Kho nrog cotter tus pin;

● Kho nrog tus neeg cog qoob loo.

Reaction pas nrig nrog roj hmab-hlau pob khawm

Nyob rau hauv thawj rooj plaub, lub crown txiv ntoo yog siv, uas, tom qab zawm, yog thaiv los ntawm ib tug cotter tus pin dhau los ntawm ib tug transverse qhov nyob rau hauv threaded ib feem ntawm tus pin.Nyob rau hauv rooj plaub thib ob, cov txiv ntoo yog tsau nrog cov cog qoob loo (caij nplooj ntoos hlav cais lub tshuab ntxhua khaub ncaws), uas tau muab tso rau hauv qab cov txiv ntoo.Tsis muaj qhov nyob rau hauv tus ntiv tes rau tus cog rau ntawm ib sab ntawm cov xov.

Ob chav kabmob pins yog rods, nyob rau hauv nruab nrab nthuav ib feem ntawm uas muaj ib tug roj hmab-hlau pob khawm.Xws li ib tug ntiv tes muaj transverse qhov ntawm ob sab, los yog ib tug los ntawm lub qhov ntawm ib sab, thiab ib tug dig muag channel nyob rau lwm yam.Cov ntiv tes tau nruab rau hauv tus pas nrig, tsau nrog cov nplhaib tuav thiab npog, O-ring tuaj yeem nyob nruab nrab ntawm lub nplhaib tuav thiab RMS.Dav hlau rods muaj peev xwm tsuas muaj ib los yog ob tug ob-txheej ntiv tes ib zaug, lub fastening ntawm xws li cov ntiv tes rau tus ncej los yog beam yog nqa tawm siv tshwj xeeb brackets nrog counter threaded rods (ntiv tes) thiab ceev.

Tus ntiv tes ntawm cov tshuaj tiv thaiv pas nrig yog ob-txhawb nrog roj hmab-hlau pob khawmD

Cov pins ntawm lub dav hlau rods yog ua los ntawm high-zoo thiab high-zoo structural carbon thiab nruab nrab carbon steels ntawm qib 45, 58 (55pp) thiab zoo sib xws, raws li zoo raws li alloy structural steels 45X thiab zoo sib xws.Lub spherical ib feem ntawm tus pin yog quenched nrog high-frequency tam sim no mus rau ib tug tob ntawm 4 mm, uas ua kom ib tug nce nyob rau hauv hardness (txog 56-62 HRC) thiab hnav tsis kam ntawm ib feem.Cov sab hauv ntawm cov hlua steel siv ua ke nrog cov qauv pob pins kuj tau quenched rau qhov zoo sib xws hardness qhov tseem ceeb - qhov no ua kom muaj kev tiv thaiv siab hnav ntawm tag nrho pob khawm.

Yuav ua li cas xaiv thiab hloov tus pin ntawm cov tshuaj tiv thaiv pas nrig

Cov ntiv tes ntawm cov tshuaj tiv thaiv rods thiab cov khoom uas cuam tshuam nrog lawv yog tas li raug rau cov loads siab, uas maj mam ua rau hnav, thiab nrog rau cov tshuab muaj zog, cov ntiv tes tuaj yeem deformed lossis puas.Qhov yuav tsum tau hloov cov ntiv tes yog qhia los ntawm qhov nce rov qab hauv lub pob sib koom ua ke, nrog rau kev pom qhov pom kev puas tsuaj rau lub tshuab.Nyob rau hauv cov ntaub ntawv no, tus ntiv tes yuav tsum tau hloov, thiab nws yog pom zoo kom hloov cov mating qhov chaw - inserts (crackers) zoo tib yam pob pins, springs, seals.

Tsuas yog cov hom thiab cov lej sau npe tau pom zoo los ntawm cov chaw tsim khoom ntawm lub tsheb lossis ncua kev kawm yuav tsum raug coj los hloov.Txawm li cas los xij, qee zaum, nws muaj peev xwm hloov tau ib lub pob tus pin nrog ib qho kev txhawb nqa RMS tus pin nrog rau kev tshem tawm cov crackers thiab lwm yam khoom.Txoj kev daws teeb meem yooj yim tshaj plaws rau kev kho yog ua tiav cov khoom siv kho, uas, ntxiv rau cov ntiv tes nws tus kheej, suav nrog cov crackers, O-rings thiab tuav cov nplhaib, springs thiab lwm yam khoom.

Kev hloov ntiv tes yuav tsum tau ua raws li cov lus qhia kho rau ib lub tsheb, tsheb npav lossis semi-trailer.Feem ntau, kev ua hauj lwm los mus rau dismantling tag nrho cov pas nrig, disassembling nws, ntxuav nws, txhim kho tus pin tshiab thiab mounting lub assembled pas nrig ntawm lub ncua kev kawm ntawv.Raws li txoj cai, ob mus rau plaub lub txiv ntseej yuav tsum tau muab tshem tawm kom tshem tawm ib tus pas nrig, thiab nyob rau hauv cov ntaub ntawv ntawm ib tug pa pob pin, pre-pinning yuav tsum tau.Teeb meem yuav tshwm sim nyob rau theem ntawm dismantling tus pas nrig, raws li cov khoom tig qaub los yog jam vim deformations, thiab disassembly yuav tsum tau siv zog ntau.Thiab qee zaum, nws yog ib qho tsim nyog yuav tsum siv cov rub tshwj xeeb.

Reaction pas nrig ua tiav nrog ntiv tes

Reaction pas nrig nrog ob-cov kabmob pins

Tom qab txhim kho lub pob pins tshiab, nws yuav tsum tau sau cov pas nrig nrog roj los ntawm cov roj lubricating, thiab cov khoom siv lubricants pom zoo los ntawm cov chaw tsim khoom yuav tsum tau siv (feem ntau Litol-24, solidol thiab zoo sib xws, nws yog qhov zoo tshaj plaws los coj cov tshuaj. daim ntawv qhia ntawm lub tsheb lubrication).Nyob rau hauv lub neej yav tom ntej, roj tshiab yog refilled nrog txhua lub caij saib xyuas.

Cov pas nrig sib dhos nrog pins yog ntsia rau hauv kev ncua siv ib lossis lwm txoj hauv kev kho cov txiv ntoo - cotter tus pin lossis tus cog qoob loo.Kev yuav khoom ntawm cov khoom no, yog tias lawv tsis tuaj raws li ib feem ntawm cov khoom siv kho, yuav tsum tau saib xyuas ua ntej.

Kev xaiv kom raug ntawm tus pin thiab nws qhov kev hloov pauv, nrog rau kev saib xyuas tsis tu ncua ntawm lub pob khawm ntawm cov tshuaj tiv thaiv rods yog ib lub hauv paus ntawm kev txhim khu kev qha thiab kev nyab xeeb ntawm tag nrho kev ncua ntawm lub tsheb, tsheb npav, semi-trailer thiab lwm yam khoom siv.

Post lub sij hawm: Lub Xya hli ntuj-11-2023